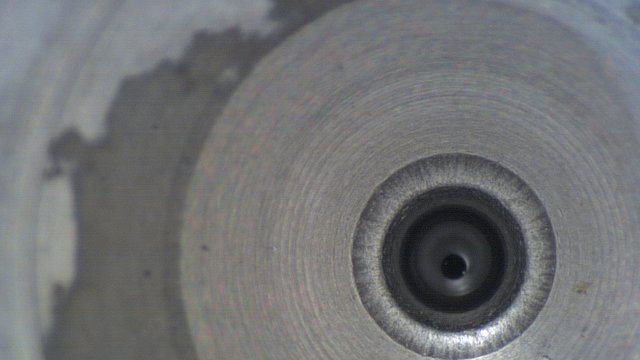

Defects in the internal components of Common Rail Diesel Injectors

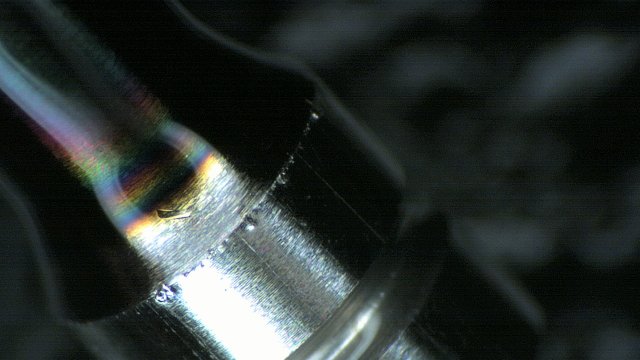

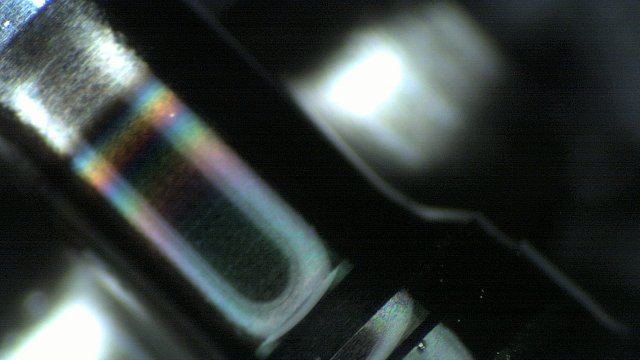

Common Rail injectors differ most from conventional (mechanical) injectors in that they work at very high pressures (300-1800 BAR). These working conditions require extremely precise parts that are part of the injectors (tolerant in subassemblies of a few microns).

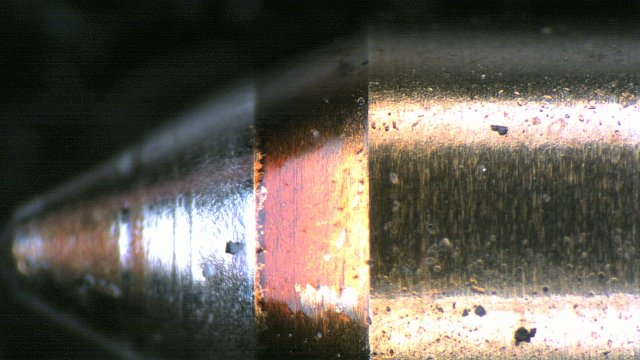

The service life of the injectors is strongly influenced by the quality of the fuel passing through them. If the fuel is fueled or in other words, if normal fuel is fueled from gas stations but the driver uses only low quality fuel filters or does not change them at intervals of 10,000 - 15,000 km then the Common injection system Rail suffers wear and tear and problems with "black smoke, heavy starting, engine thrust, ...".

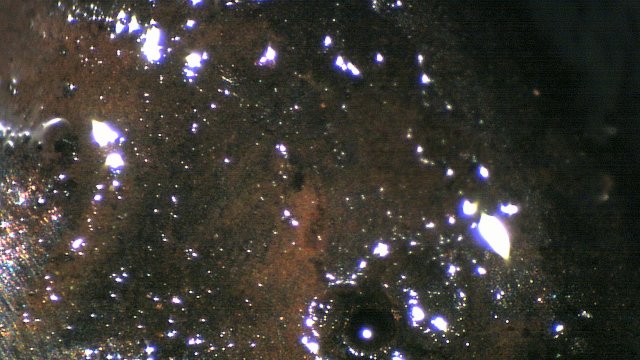

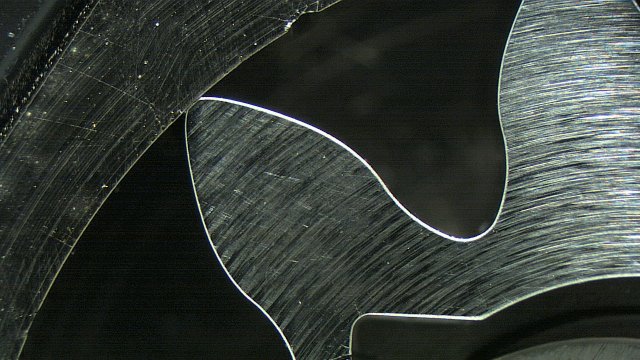

In these pictures taken under a microscope we have examples that show wear inside the injectors caused by: impurities, wrong fuel, water and metal filings.