Geometry Calibration and Balancing for Turbochargers

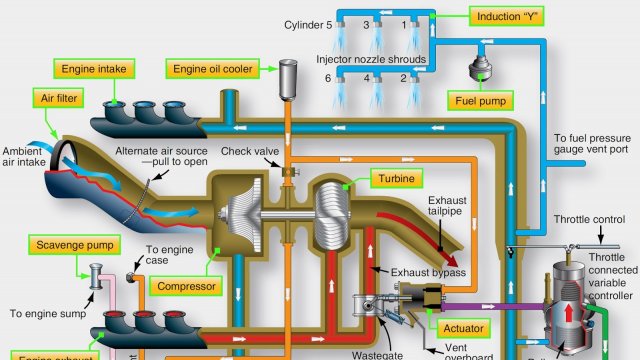

For a complete turbocharger repair you need:

- a specialist who knows the process (can give you information about the cause of the defect that must be remedied before installing a new or repaired turbine)

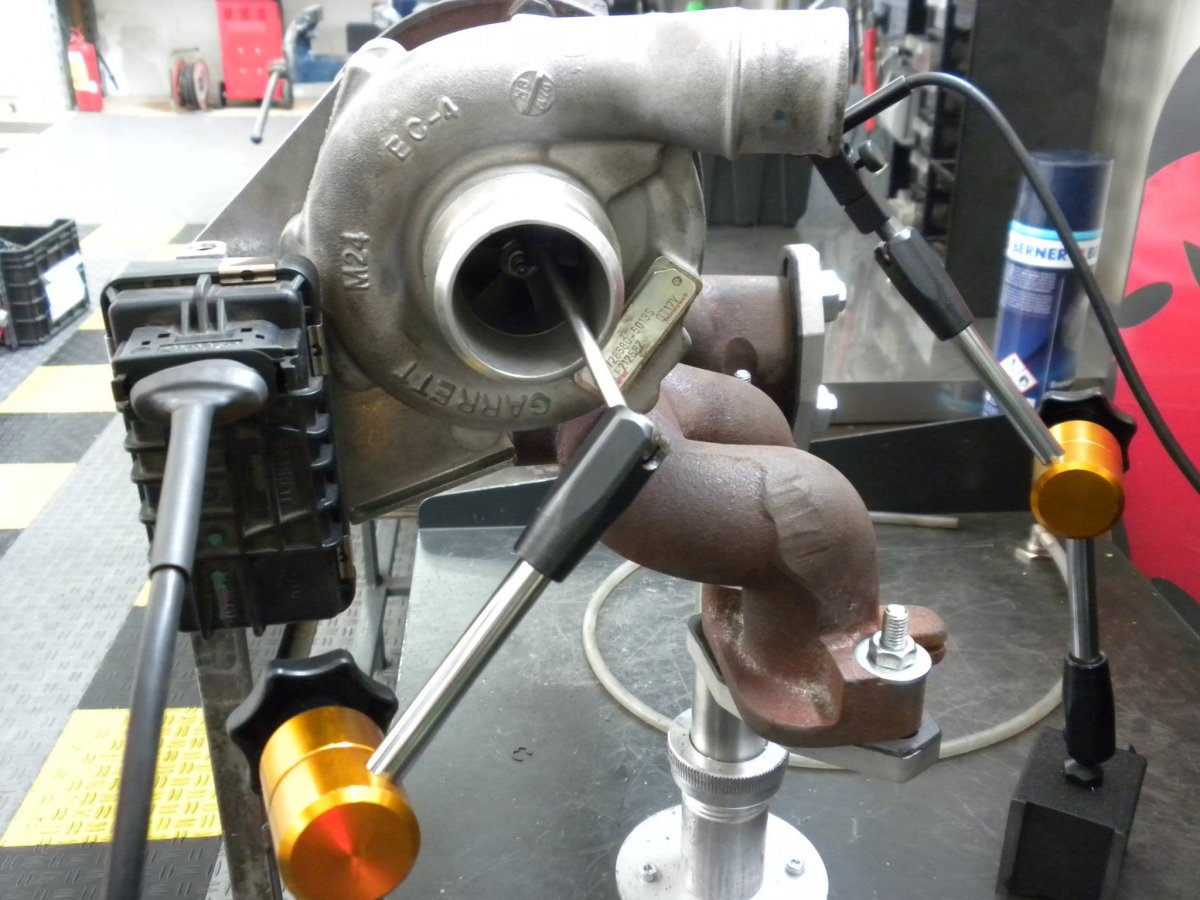

- (new) quality components to replace the used ones

- dedicated equipment for component cleaning, dynamic component balancing and final VNT adjustment (for turbochargers with variable geometry, can be operated by pneumatic valve or electronic actuator)

These steps are strictly followed in our workshop. We place a lot of emphasis on the customer's consulting part regarding the correct installation of the turbocharger and the engine cleaning procedures before the turbine assembly. In this way we manage to obtain a high level of trust from the clients who recommend us further.